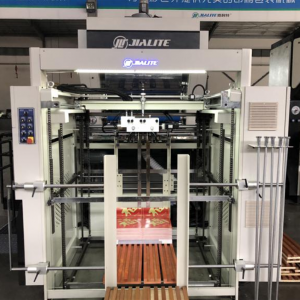

NFM-H1080 Automatic Vertical Laminating Machine

| Model | FM-H |

| FM-1080-Max.pepa saizi-mm | 1080×1100 |

| FM-1080-Min.pepa saizi-mm | 360×290 |

| Speed-m/min | 10-90 |

| Pepa ukobvu-g/m2 (kuchekwa kwebanga) | 80-500 |

| Pepa ukobvu-g/m2 (banga rinopisa richitsemura) | ≥115gms |

| Kunyatsopindirana-mm | ≤±2 |

| Firimu ukobvu (yakajairika micrometer) | 10/12/15 |

| Kazhinji glue ukobvu-g/m2 | 4-10 |

| Pre-gluing firimu ukobvu-g/m2 | 1005,1006,1206 |

| Non-stop Kudyisa kureba-mm | 1150 |

| Muunganidzi mapepa urefu (incl. pallet) -mm | 1050 |

| Power | 380V-50Hz-3Pkupisa simba:20kwkushanda simba: 35-45kwTotal power stand by:75Kw Mupazi wedunhu:160A |

| working pressure-Mpa | 15 |

| Vacuum pombi | 80psiSimba: 3kw |

| Air compressor | Kuyerera kwevhoriyamu: 1.0m3/min,Rated pressure: 0.8mpaSimba:5.5kwPipe yekupinzaDia.8mm (kurudzira kushandisa Centralized air source) |

| Cable ukobvu-mm2 | 25 |

| Kurema | 9800kgs |

| Dimension (kurongeka) | 8400*2630*3000mm |

| Loading | 40HQ |

FEDDING UNIT

1. Servo Motor Feeder, 4 suckers yekusimudza uye 4 suckers yekufambisa chimiro.Max Speed 12000 mapepa / h.

2. Itafura yekudyisa mapepa ine yepamusoro uye yakaderera pamusoro pekudzivirira kwepamusoro.

3. Kureba kwekudya kusina kumira kunogona kusvika 1150mm, pre-stacking device, non-stop feeding.

4. Hungwaru gadziriso yepamberi uye kumashure zvinzvimbo zveFeeder, kungoisa chigadzirwa data pane control panel.

5. BECKER VACUUM PUMP

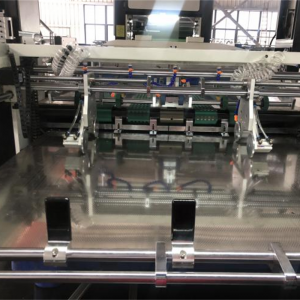

TAFURA YEKUTAURA UYE KUBAYANA

1.The conveying tafura adopts customized Stainless corrugated board.

2.Gumbo rebhurashi uye vhiri rekutsikirira rabha rinofamba zvakanaka.

3.Servo mota inopindirana, kuvandudza kurongeka kwemakumbo, kukanganisa≤± 2mm.

DUST REMOVER UYE WINDOW LAMINATING(ZVINODA) Poder remover hwindo coator uye dryer.

Single heat roller poda remover device (optional) ine compact structure, chikuva chine basa rekusveta kuti ive nechokwadi chekuti bepa kuburikidza nehupfu yekubvisa mudziyo haichinji.

Kubvisa guruva kunogona kubvisa guruva pamusoro pepepa mushure mekudhinda kudzivirira mavara machena mushure mekunge bepa rakaputirwa.

Zvinoenderana nezvinodiwa nevatengi kuisa inkjet mudziyo patafura yekubvisa huruva, inkjet uye muchina welaminating unoonekwa nemuchina mumwe.

Inkjet tafura inogonawo kusarudzwa yakazvimirira.

Window coating (inosarudza), inoumbwa negluing muchina musoro uye infrared oveni.Mushure mokunge pepa racho rakanamwa, rinosungirirwa kune firimu mushure mokupfuura muvheni ye infrared.

Drying unit ine 12 pcs IR chiedza, Total kudziyisa simba 14.4kw.

Kana usingashandisi zvigadzirwa zvemahwindo, chikamu ichi chinogona kushandiswa semvura yekubvisa poda mudziyo.

LAMINATOR HOST

Kuomesa roller dhayamita yakawedzera kusvika 1000mm, uchishandisa electromagnetic kudziyisa system.

Iyo yekupisa yekupisa roller inotora yakakamurwa kudziyisa system, inoshanda uye inochengetedza simba.

Kunyanya kudzvinyirira kwe press roller ndeye 12T.

Glue roller uye metering roller inofambiswa nemamota maviri akazvimirira, zvichiita kuti kugadzirisa kuve nyore.

Gluing system Teflon process kurapwa, iri nyore kuchenesa uye isina kunamira.

Waste film winding device.

CUTTING UNIT

Iyo yekucheka mapepa ine tension controller uye anti-curl mudziyo kuti ive nechokwadi chekuti bepa rakati sandara uye harina kumonereka.

Chikamu chekucheka bepa chine vhiri rekukuya, banga redhisiki uye banga rinopisa rekutsemura, kusangana nezvinodiwa nevatengi zvekutsemura mafirimu emhando dzakasiyana.

Iyo bounce roller inodzorwa nemota yakazvimirira, uye bepa rinogona kupatsanurwa nekushandisa mutsauko wekumhanya.

Banga rinopisa rakaderera kudzvanya kwakananga kupisa uye kutsemura pasina muswe firimu, kuona bepa ukobvu uye kutsemuka, kwakaringana uye kunoshanda.

USINA-KUMIRA MUKONDI

Iyo isingamisiki yekuunganidza kureba inogona kusvika 1050mm.Kana iyo stack inenge yazara, bhandi rekutakura rinobva rawedzera kubvuma bepa.Iyo yekuunganidza chikuva ichadonha.Mushure mekunge tireyi yatsiviwa, chikuva chinozodzokorodza uye kupedzisa iyo isina-kumira muunganidzi.

Gamuchira pneumatic mapepa ekugadzirisa chimiro kuti uve nechokwadi chekuchena kwepepa uye kufambisa nzira inotevera, ine vhiri rekudzikisa kudzivirira bepa kuti risakuvare nekuda kwekunyanya kurova baffle.

Kuverenga ziso remagetsi, nhamba yepepa rinomhanya rinoratidzwa pachiratidziro chekuratidzira pamushini wekutora, unogona kucheneswa uye kuunganidzwa.

Induction ziso remagetsi, kunzwa kureba kwepepa, kana urefu hwepepa huchichinja, bhanhire rinokurumidza, uye baffle yemuchina wekutora uchapidigura nekusimudza pepa.

Musimudza firimu

Spare parts