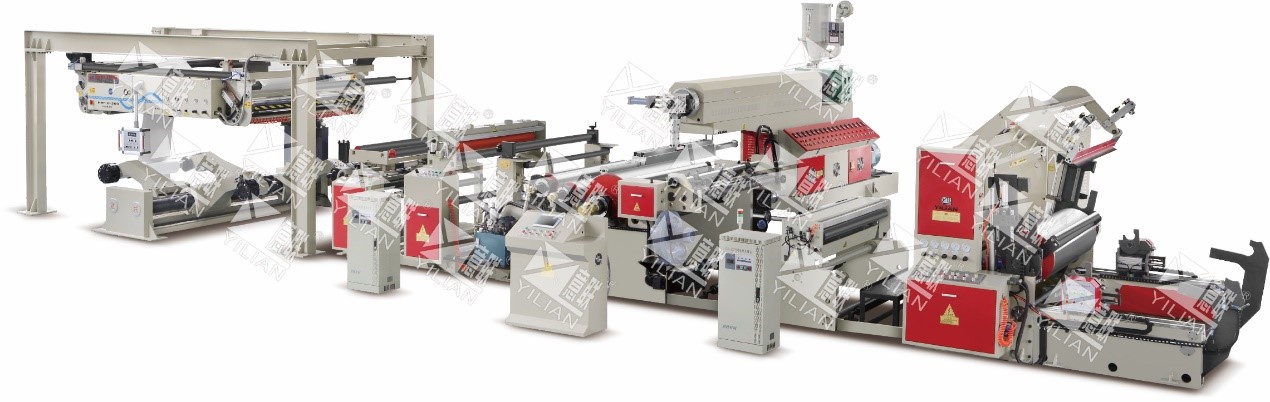

WSFM1300C Otomatiki Pepa PE Extrusion Coating Machine

| Inokodzera laminating resin | LDPE, PP nezvimwe |

| Sutu base zvinhu | bepa (80-400g/m²) |

| Max mechanical kumhanya | 300m/min (kumhanya kwekushanda kunoenderana nekukora kwehuputi, hupamhi) |

| Coating width | 600-1200, mutungamiri roller upamhi: 1300mm |

| Coating ukobvu | 0.008—0.05mm (Sirufa imwe) |

| Coating ukobvu kukanganisa | ≤±5% |

| Auto tension setting range | 3-100kg yakazara margin |

| Max extruder uwandu | 250 kg/h |

| Compound cooling roller | ∅800×1300 |

| Screw Diameter | ∅110mm ratio35:1 |

| Max kusunungura dhayamita | ∅1600mm |

| Max rewind dhayamita | ∅1600mm |

| Unwind bepa musimboti dia :3 ″ 6 ″ uye Rewind bepa musimboti dhayamita: 3 ″ 6 ″ | |

| Extruder inotyairwa ne45kw | |

| Total power | anenge 200 Kw |

| Machine uremu | anenge 39000kg |

| Kunze dimension | 16110 mm×10500 mm × 3800 mm |

| Muchina wemuviri ruvara | Grey uye Tsvuku |

1. Unwind chikamu (nePLC, servo unwinding)

1.1 Unwind furemu

Chimiro: Hydraulic shaft-isina kusunungura furemu

Iyo BA yakatevedzana splicer inoumba chikamu chakakosha cheiyo lamination mutsara uye inoiswa pamusoro peiyo roll stand pazasi pebhiriji chimiro. Inobvumira kuenderera mberi mukumhanya kweiyo iripo mapepa roll kune inotevera bepa roll pasina kumira kwekugadzirwa.

Mukati me splicer side mafuremu mune 2 inofambiswa splicing musoro uye inofambika yepakati tsigiro chikamu. Pamusoro payo pane 2 nip rolls.

Iyo capstan roll, reverse idler roll uye kaviri dancer system inoumba chikamu chekuunganidza bepa icho chinokwanisa kuunganidza bepa rinosvika 4 zvakapetwa kureba kweiyo splicer.

Muchina unoshandiswa kuburikidza nepaneru yekuvhiya pamushini

Pepa rinobatanidza kumhanya Max.300m/min

a)apo simba repepa riri pamusoro pe0.45KG/mm, max. 300m/min;

b)apo simba repepa riri pamusoro pe0.4KG/mm, max. 250m/min;

c)apo simba repepa riri pamusoro pe0.35KG/mm, max. 150m/min;

Paper width

Max. 1200mm

Min. 500mm

Kumhanya CE-300

Max. 300m/min

Pneumatic data

Seta kumanikidza 6.5 bar

Min. pressure 6 bar

Muenzaniso CE-300

Simba 3.2kVA, 380VAC/50Hz/20A

Kudzora voltage 12VDC/24VDC

1.1.1 Yakazvimirira hydraulic shaft spindle clamp ruoko rudzi kaviri yebasa-chiteshi kusunungura, isina mweya shaft, hydraulic kurodha, chengetedza mutengo wekurodha mechaniki chimiro. Otomatiki AB shaft otomatiki reel alternation, kushomeka kutambisa zvinhu.

1.1.2 Max. kusunungura dia.: ¢1600mm

1.1.3 Auto tension setting range :3-70kg full margin

1.1.4 tension chaiyo: ± 0.2kg

1.1.5 bepa musimboti:3” 6”

1.1.6 Tension control system: shaft mhando yetension detector neiyo chaiyo potentiometer yekuona tension, iyo yepakati kutonga kwe programmable PLC.

1.1.7 Dhiraivha control system: PIH silinda braking, iyo inotenderera encoder mhinduro nekukurumidza, chaiyo kudzvanywa inodzora vharafu yakavhara loop control, programmable controller PLC centralized control.

1.1.8 Tension setting :Nekunyatsodzvanya kunodzora vharafu

1.2 Kuchengeta mhando yekunhonga otomatiki, yekucheka mudziyo

1.2.1 Kuchengeta kunotyairwa nepneumatic motor buffer, chengetedza kugadzikana kwakagadzikana paunenge uchinhonga bepa.

1.2.2 yakasiyana yekucheka chimiro

1.2.3 PLC otomatiki kuverenga nyowani shaft inotenderera kumhanya, uye chengetedza kumhanya nekumhanya kukuru kwemutsara

1.2.4 Gamuchira zvinhu zvekudzvanya roller, cutter yakapwanyika zvinhu .tension control shanduko, reset zvese zvinogona kupera otomatiki

1.2.5 Roller shanduko yepamberi alarm,: dhayamita yebasa kana yasvika 150mm., muchina ucharidza alarm

1.3 Kugadzirisa kutonga: photoelectric putter kugadzirisa kudzora system (bst chimiro)

2. Corona (Yilian customized)

Corona kurapwa simba :20 kw

3. Hydraulic lamination unit:

3.1 Matatu ma roller laminating compound structure, back press roller, anogona kugadzira compound roller bere simba nyangwe, komboni yakasimba.

3.2 Kubviswa kwesilicon rubber roller: chigadzirwa chemukomboni chiri nyore kutarisa kubva pakutonhodza roller, Hydraulic inogona kudzvanya zvakasimba.

3.3 Iyo yakakomberedzwa roll firimu flattening chimiro,: inogona kuita kuti firimu rikurumidze kutumirwa

3.4 Compound feed material inogadzirisa roller inogona kukunda firimu zvinhu ukobvu kusaenzana uye zvichingodaro kushaya simba

3.5 High pressure blower inoyamwa zvimedu nekukasira.

3.6 Compound outlet cutter roller

3.7 Compound roller inofambiswa nemotor zvinoenderana

3.8 Compound roller driven motor inodzorwa neJapan frequency controller

Mutengo:

(1) compound roller: ¢ 800 × 1300mm 1pcs

(2) rabha roller: ¢ 260 × 1300mm 1pcs

(3) dhinda roller: ¢ 300 × 1300 mm 1pcs

(4) kubatanidza silinda yemafuta:¢63 × 150 2pcs

(5) bvisa roller: ¢130 × 1300 1pcs

(6) 11KWmotor (SHANGHAI) 1set

(7) 11KW Frequency converter (JAPAN YASKAWA)

(8) tenderera chekubatanidza: (2.5"2 1.25"4)

4. Extruder (auto urefu kugadzirisa)

4.1 Chikuro dhayamita:¢ 110,Max extruder nezve:250kg/h (Tekinoroji yeJapan)

4.2 T-die (Taiwan GMA)

4.2.1 Mold width: 1400mm

4.2.2 Mold inoshanda hupamhi: 500-1200mm

4.2.3 Mold lip gap: 0.8mm, kukobvu kwekuvhara: 0.008-0.05mm

4.2.4 Coating ukobvu kukanganisa: ≤± 5%

4.2.5 Magetsi ekupisa chubhu mukati mekupisa, kupisa kwakanyanya kunoshanda, tembiricha inowedzera nekukurumidza

4.2.6 Yese yakavharirwa ndima, Stuffing upamhi kugadziriswa

4.3 Kurumidza shanduko yetiweki zvishandiso

4.4 Kumberi uye kumashure kufamba, kunogona kusimudza Trolley, kusimudza renji: 0-100mm

4.5 Mold 7 nzvimbo tembiricha kutonga. Screw barrel 8 chikamu chekudzora tembiricha. connector 2 nzvimbo yekudzora tembiricha inotora infrared heat unit.

4.6 hombe simba rekudzikisira giya bhokisi, HARD ZINO (Guo tai guo mao)

4.7 Digital tembiricha controller otomatiki tembiricha kudzora

Zvikamu zvikuru:

(1) 45kw AC mota (SHANGHAI)

(2) 45KW frequency converter (JAPAN YASKAWA)

(3) Digital tembiricha controller 18pcs

(4) 1.5KW kufamba mota

5.Pneumatic Round banga rokucheka mudziyo

5.1 Trapezoidal screw transverse kugadzirisa mudziyo, shandura hupamhi hwekucheka bepa

5.2 Pneumatic Pressure cutter

5.3 5.5kw high pressure edge inopinza

6.Rewinding Unit: 3D inorema basa chimiro

6.1 Rewinding Frame:

6.1.1 Friction mhando yemagetsi kaviri zviteshi zvekudzosera kumashure muchina, yakakwira-kumhanya otomatiki kucheka uye kunhonga zvinhu zvakapedzwa, kuburitsa otomatiki.

6.1.2 Max. kudzosera dhayamita: ¢ 1600 mm

6.1.3 roll-over kumhanya:1r/min

6.1.4 kushushikana: 3-70kg

6.1.5 Tension chaiyo: ± 0.2kg

6.1.6 bepa musimboti: 3″ 6″

6.1.7 Tension Control System: Iyo cylinder cushion inoyangarara iyo inoyangarara roller mhando chimiro, tension inoonekwa neiyo chaiyo potentiometer, uye iyo programmable controller PLC inodzora tension. (Japan SMC yakaderera friction silinda) 1 set

6.1.8 Drive Control System: 11KW motokari motokari, rotary encoder speed mhinduro, Senlan AC inverter mbiri yakavharwa-loop control, programmable controller PLC centralized control. 1 set

6.1.9 Constant Tension Setting: Precision Pressure Regulator Setting (Japan SMC)

6.1.10 Taper tension setting: zvechimbichimbi zvakasetwa nekombuta sikirini, PLC control, kutendeuka nemagetsi/air ratio (Japan SMC)

6.2 Otomatiki Kudyisa uye Kucheka Chishandiso

6.2.1 Splicing Support Rollers inodzorwa nePLC kutyaira mota kuti ibatisise zvinhu kure nerubbing roller.

6.2.2 Hydraulic Independent Cutter Mechanism

6.2.3 PLC otomatiki kuverenga kwemaitiro ekunhonga, kutsiva kwevhoriyamu kunopedzwa nekiyi.

6.2.4 Basa Rekutsigira Roller, Kucheka Material, Reset, etc. Yakapedzwa Otomatiki

6.2.5 Zvinotsanangurwa

(1) Friction roller: ¢ 700x1300mm 1 bar

(2) Winding motor: 11KW (Shanghai Lichao) 1 set

(3) Kukungurutsa giya bhokisi: yakaomeswa pamusoro helical giya inoderedza (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 set

(5) Tsigira roller gear box: 1 seti yesimba

(6) Speed inoderedza: zino rakaoma 1 seti yesimba

(7) Rolling yekufamba kumhanya inoderedza: 1 seti yesimba

(8) Kuburitsa hydraulic station

7.Auto air shaft puller

8.Drive Chikamu

8.1 Main mota, bhandi rekufambisa rinotora bhandi rinoenderana

8.2 Kubatanidza, kudzosera uye kusunungura mota: Dhiraivha bhandi tora arc giya, cheni uye synchronous bhandi kufambisa

8.3 Main dhiraivha giya bhokisi: Kuisa chisimbiso mafuta-akanyudzwa helical giya, Mutsetse helical gear transmission chimiro

9.Control Unit

Yakazvimirira magetsi kabati, centralized control, iyo inoumbwa nzvimbo ine centralized control cabinet operation. Muchina otomatiki sisitimu uchishandisa seti yePLC (hollsys) mudziyo une yakakwirira kugadzirisa kugona, uye man-muchina dialogue masaini uchishandisa network kutaurirana pakati peiyo interface. PLC, extrusion unit, man-machine dialogue interface pakati pekutyaira system uye inoumba yakabatanidzwa otomatiki control system. Nokuti chero parameters anogona kuseta, pamwe otomatiki kukarukureta, chiyeuchidzo, kuona, aramu, etc. Inogona tension of anoona kuratidza mudziyo, kumhanya, coating ukobvu, kumhanya uye akasiyana kushanda mamiriro.

10. vamwe

11.1 Inotungamira Roller: Yakaoma anodization yealuminium alloy gwara rekutungamira, maitiro ekufamba

11.2 Low voltage midziyo yeFrance Schneider, omron Japan, nezvimwe.

11.parts brand

11.1 PLC (Beijing Hollysys)

11.2 Bata skrini (TAIWAN)

11.3 frequency converter:Japan Yaskawa

11.4 Main mota: SHANGHAI

11.5 yakaderera friction silinda (Japan SMC)

11.6 AC CONTACTOR (Schneider)

11.7 bhatani (Schneider)

11. Static musanganisi (Taiwan)

11.9 cylinder pressure inodzora vharafu (Taiwan)

11.10 Magnetic exchange valve (Taiwan)

11.11 chaiyo kudzvanywa inodzora vharafu (SMC)

12.Customer self inopa zvivako

12.1 Equipment nzvimbo uye hwaro

12.2 Zvishandiso zvinopihwa zveMuchina magetsi kabati

12.3 Kupihwa kwemvura kunzvimbo dzemuchina mukati nekunze kwegedhi (mutengi anogadzirira chiller chemvura)

12.4 Gasi rekupa muchina wakaiswa mukati nekubuda mudumbu

12.5 Pombi yekuburitsa uye feni

12.6 Unganidza, kurodha uye kuburitsa zvinhu zvepasi mudziyo wapera

12.7 Zvimwe zvivakwa zvisina kunyorwa muchibvumirano

13. Spare parts list:

| Aihwa. | Zita | Spec. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Temperature controller | Omroni |

| 3 | Micro-regulating valve | 4V210-08 |

| 4 | Micro-regulating valve | 4V310-10 |

| 5 | proximity switch | 1750 |

| 6 | Solid relay | 150A pamwe ne75A |

| 7 | kufamba chinja | 8108 |

| 10 | kupisa unit | ϕ90*150mm,700W |

| 11 | kupisa unit | ϕ350*100mm,1.7KW |

| 12 | kupisa unit | 242*218mm,1.7KW |

| 13 | kupisa unit | 218*218mm,1KW |

| 14 | kupisa unit | 218*120mm,800W |

| 15 | Schneider bhatani | ZB2BWM51C/41C/31C |

| 16 | mhepo jongwe | |

| 17 | Tepi yepamusoro yekushisa | 50mm*33m |

| 18 | telflon tepi | |

| 19 | Corona roller cover | 200*1300mm |

| 20 | Pepa remhangura | |

| 21 | skrini sefa | |

| 22 | Denderedzwa zvidimbu | 150*80*2.5 |

| 23 | pneumatic connector | |

| 24 | pfuti yemhepo | |

| 25 | mubatanidzwa wemvura | 80A ne40A |

| 27 | screws nevamwe | |

| 28 | dhonza cheni | |

| 29 | bhokisi rekushandisa |

Zvikamu zvikuru uye mufananidzo:

Unwinder (Auto splicer) → webhu inotungamira → Corona murapi → Kuwedzeredza uye kusanganisa chikamu Edge Trimming → Kudzosera shure